Module 3 - Gearbox

Module 3 Build:<2nd October 2005>

Gearbox Preparation:

Gearbox Preparation:I started to look at the gearbox this morning. Trying to work out how everything will fit together. The gearbox is the MT75 which was fitted in the later Sierras and Granada's, i believe it was also fitted to cosworths but i may be wrong! I got mine completely rebuilt and reconditioned from Donor Spares and whilst not cheap, as you can see from the picture it has arrived looking very clean and i get a 12 month warranty with it. After a quick check it turns freely and was able to select all the gears easily. This doesn't really tell me too much about its condition but at least its a start.

This picture shows the inside of the bellhousing. You can see i have fitted the clutch arm and standard thrust baring over the main shaft. There is a mounting point on the outside edge of the bellhousing for the clutch cable to slot into. The cable then goes through and attaches to the end of the clutch arm. Its a simple mechanism that, when the clutch is pressed the cable is pulled which then in turn pulls the clutch arm towards the clutch. The thrust baring is attached to the center of the clutch arm and so this is pressed into the out casing of the clutch flexing the plate which moves the plate away from the clutch, thereby disengaging the clutch. The Standard trust baring needs to be replaced with the one i have from Westfield, which is about twice the length and so makes up for the MT75 bellhousing being longer.

This picture shows the inside of the bellhousing. You can see i have fitted the clutch arm and standard thrust baring over the main shaft. There is a mounting point on the outside edge of the bellhousing for the clutch cable to slot into. The cable then goes through and attaches to the end of the clutch arm. Its a simple mechanism that, when the clutch is pressed the cable is pulled which then in turn pulls the clutch arm towards the clutch. The thrust baring is attached to the center of the clutch arm and so this is pressed into the out casing of the clutch flexing the plate which moves the plate away from the clutch, thereby disengaging the clutch. The Standard trust baring needs to be replaced with the one i have from Westfield, which is about twice the length and so makes up for the MT75 bellhousing being longer.The other end of the gearbox holds the propshaft joint. As you can see from the pics below this consists of a 3 pronged bracket on the gearbox shaft and a rubber anti vibration flange to fit between that and the propshaft. I was only sent 2 bolts with the gearbox but after a quick call to Andy at Donor Spares he is sending me the third one.

<4th October 2005>

I fitted the Westfield modified Thrust Baring to the clutch arm and then attached the clutch arm in place in the bellhousing. I then test fitted the gearbox into place so i could check which parts of the bellhousing would need to be removed / trimmed for the box to fit comfortably where it is supposed to. This also gave me the chance to see roughly where the engine will be sitting and so check the clearances for the water pipes and coil pack. It seems that while its going to be tight, it will fit ok.

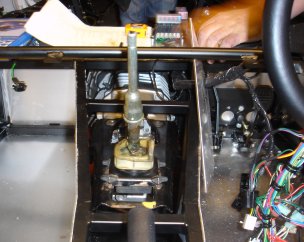

Seeing the standard MT75 gear stick in place I'm glad i went for the quick shift! As you can see from the pictures below the standard stick is rather large and i would also need to trim a fair bit from the original mounting due to it being a bit bulky. As you can see from the picture i have removed the original shifter bracket as i will soon have the quick shift to fit on in its place.

I also ordered the reverse lamp switch from Westfield and it has arrived. However as you can see in the pic below, although it appears it would fit perfectly into the MT75 box, the plug from the Westfield loom is a completely different shape?!?

I have mailed the parts department and look forward to the response!

<11th October 2005>

Started to make the preparations to the gearbox ready for fitting. The first thing to do was grind down the original mounting blocks. As you can see from the pictures below there were 4 protruding blocks, 2 one the bellhousing and 2 on the main body of the box. They only needed trimming back so i erred on the side of caution and just took them back as far as i felt necessary.

Next i wanted to fit the quick shifter. So after removing the original mounting brackets i fitted the quick shift mountings into the same mountings. the tricky bit was fitting the actual selector. I found the easiest way to do this was to put an allan key through the bolt hole in the quick shift selector and align it with the spring loaded gearbox selector. Once it was lined up i could push the allan key out with the bolt and then simply fasten it in place. I quickly test the gear changes and i can honestly say i was amazed! For anyone not convinced if its worth doing or not i would say a definite yes, the throw is now incredibly short and the selection is do direct. I really didn't think it would make as much of a difference as it did.

The last thing to do to the gearbox before fitting is replace the reverse sensor. So i removed the original one and put the new Westfield one in its place. I am still awaiting the adaptor to fit this to the main loom but I'm assured i will get that soon.

Copyright ©2012

Kevin Baldwin

Copyright ©2012

Kevin Baldwin